12 or 24 Volt LED Strip Light – What’s Best?

In this blog we discuss the differences between 12V and 24V LED strip light. Their pros and cons and which you should use for your application.

Low and medium power LED strip (less than 15 watts/metre) is generally available in both 12V and 24V versions, whereas higher brightness strip (15 – 30 watts/metre) is generally only available in 24V. There are a number of factors to consider when deciding which voltage to use for a particular application.

BRIGHTNESS

There is no inherent difference in brightness between a 10W/m 12V strip and a 10W/m 24V strip (using the same type of LEDs). Both use much the same power and produce much the same light output.

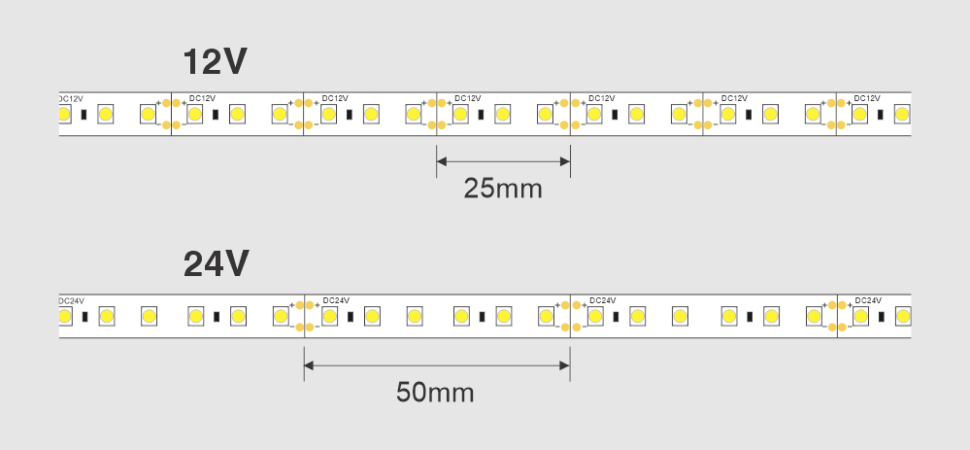

CUTTING DISTANCE

White LEDs used on strip typically require 3.0 – 3.5V to operate. On a 12V strip, they are connected in strings of 3 with 1 dropping resistor. For 24V, it is typically 6 and a dropping resistor. For the common 120LED/m strip, this means a cutting interval of 25mm for 12V, and 50mm for 24V. For a given type of strip, the cutting distance for 24V is always double that of 12V.

If your job requires short lengths of LED strip (eg backlighting the letters in a sign), then 12V has the definite advantage.

MAXIMUM LENGTH OF A RUN

The rule is that Power (in Watts) = Current (in Amps) X Voltage (in Volts).

Therefore, a 12V strip will draw twice the current of an equivalent 24V strip. LED strip is made from copper foil, on to which the LEDs and resistors (sometimes other components, as well) are soldered. The copper foil is not a perfect conductor, and losses occur (which become heat). These losses contribute to voltage drop along the length of the strip. If the input voltage at the beginning of a 5m 12V strip is 12V, this may reduce to 10V by the end of the strip. This means that the remote end LEDs will not be as bright as the ones at the start.

Voltage drop is directly proportional to current, and we just learnt that 12V strips use twice the current of 24V strips. Therefore, the voltage drop effect is twice as great for 12V strip as it is for 24V strip.

For longer runs, therefore, 24V has definite advantages over 12V.

However, even 24V strip starts to suffer from compound voltage drop when used in lengths greater than about 7 or 8 metres.

There are several possible solutions.

- The strip length can be doubled by powering it from both ends

- Using constant current strip. This technology uses, in addition to the series resistor/s in each block of diodes, voltage regulator ICs in each block of LEDs. Typically, lengths of 15 – 30m are achievable (powered from one end). The extra components required increase the price somewhat.

Typically, LED strip is made from “ 2oz copper” or “3oz copper”. This refers to the thickness of the copper foil which is the base of the strip. 3oz copper is thicker, therefore produces less voltage drop, but at a slight increase in cost.

AUTOMOTIVE/MARINE APPLICATIONS

Cars and small boats typically have 12V systems, so it is logical to use 12V strip. Larger boats however may be 24V, so 24V LEDs would generally be more expedient.

WIRING CONSTRAINTS

We learnt above that the currents (amps) required in a 24V installation is half that for a 12V installation. If the distance between the driver and the start of the LED strip is greater than a metre or two, the voltage drop in this cable may need to be considered.

For longer lengths, 24V systems offer an obvious advantage. This also enables the use of lighter gauge cable (and connectors).

CONTROLLERS

In many applications, controllers such as dimmers and RGB controllers are used. These typically have a maximum current rating of 5 – 8A per channel. The current rating is generally the same for 12V or 24V, so 12V x 5A = 60W, and 24V x 5A = 120W. We see then that using 24V enables the same controller to control twice the load of a 12V system.

DC TO DC CONVERTERS

In an upcoming blog we will discuss in greater detail the use of DC / DC converters, which can change 12V to 24V, or vice versa. They can offer options to circumvent restrictions in some installations.

© 2022 Linear Lux

Browse our wide range of LED Strip Lights HERE